Cutting metals can be a costly process and many manufacturers that shape parts from raw materials may be unaware of how the latest sawing machines and technology apply to their own operations and how they can save costs by using the right tools.

Abrasive saws are the machine of choice for on-demand cutting of specialty steels and alloys, according to Mike Abbas, Director of Engineered Systems and Cutting Products at Thermatool Corp., East Haven, Connecticut. Savage Saws, a product line of Thermatool Corp., is among the pioneers of abrasive cutting and continues to develop this highly productive technology.

Manufacturers want equipment that features quick-change tooling, computerized setup, recipe-driven processes, high reliability, ease of maintenance and high throughput, says Abbas.

Thermatool Corp. builds an abrasive saw product line with power options ranging from 10 to 500 HP, which includes a small guillotine, gantry, plate, rotator, super saw, and foundry saw. The material can be cut dry, wet, or at high temperatures. Saw capacities can range from ¼ up to 36 inches in diameter, using abrasive blades that are 1/32 to ½-inch thick, and from 14 to 60 inches in diameter. Savage Saws can also utilize carbide tip blades which are available for cutting nonferrous materials.

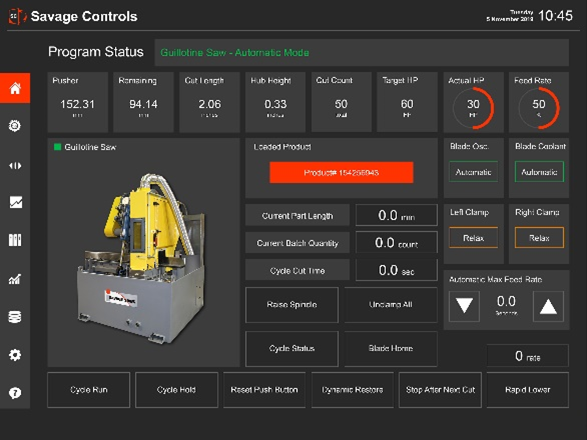

Blade oscillation, step cutting, electronic length control, and recipe driven batch cutting are some of the key features included with Savage Saws. Fully automated controls are available from the operator console with a menu-driven touch screen, says Abbas. Optionally, custom or standard material handling solutions can be purchased and integrated for fully automated production.

Cutting Application Example

Founded in 1917, Parker Hannifin Corp., based in Mayfield Heights, Ohio, is a global manufacturer that reported nearly $14.4 billion in revenues last year. It designs and builds motion and control systems for a vast array of end markets, including defense and aerospace, commercial marine, automotive and industrial robotics. Some of the products Parker makes include motors, gaskets, valves, fittings and couplings, sensors, and monitors. A major division of Parker produces metal-intensive pneumatic and hydraulic cylinders and related accessories.

Dan Sayre, a Manufacturing Engineer for Parker Hannifin, says the company operates four abrasive saws sourced from Savage Saws. “These saws cut grade 1045 carbon steel and some grade 17-4PH stainless steel,” he says. The resulting parts are then machined into piston rods for pneumatic or hydraulic cylinders.

The usage rates on the saws “vary per facility, between 10 to 14 hours per day,” Sayre says.

Size and Speed Matter

One of the primary reasons Parker Hannifin chooses Savage Saws abrasive cutting machines is due to its ability to switch between product sizes rapidly without the need for tooling changes, we can go from cutting ½ inch diameter up to 5-1/2-inch diameter with ease. With Savage Saws, you can program the saw and cut any diameter on the fly. “If you want to cut that range on a band saw, you will need three blade changes,” Sayre says, “which means 15 minutes per changeover, not to mention the risk of harm to the operator during the blade change.”

The carbide tip blades used with a band saw cost $500 to $600 per blade. If an operator breaks a blade, it’s money down the drain. The band saw’s drives and rollers get torn up as well,” he continues.

“With the correct blade on a band saw machine, they can get through a 5-1/2 inch diameter bar in 15 minutes. On an abrasive saw, operators are able to cut that same material in only 3 minutes,” notes Sayre.

The only drawback with using an abrasive blade, says Sayre, is the dust and dirt it creates but that can be readily offset by a “good operator who keeps the machine clean and maintains the coolant,” so the saw “runs and runs.”

“As far as running the saw, it does what we need it to do.” With the automation features available on the Savage Saws, “You can teach an operator in a shift or two and run the saw independently. Compared with a band saw, a more experienced operator is needed. With Savage Saws, you hit the green button and go.”

Sayre says Parker Hannifin expects great service and support from Savage Saw. However, because of the high reliability of the equipment, “I haven’t had to make any calls about service. In our division,” he adds, “we have had very few questions about the saw, and with the quick response from Thermatool Corp.-Savage Saws customer service we got the answers immediately.”

The newest saw was installed recently in Oregon, he says. “We are looking to install a fifth unit soon.”

Faster Cycle Times

The major advantage of an abrasive saw over a band saw are high cut rates, increased quality of cut, the ability to work on hot or cold material, and high productivity when cutting high strength materials. Also, abrasive saws consume less floor space and requires fewer operators, says Abbas.

A 10-inch-thick titanium billet requires 45 minutes to make one cut on a band saw, but with an abrasive saw it only takes 5 minutes. Using a Savage Saw model SG-150, cutting a 4-inch billet takes 45 seconds while a band saw could take up to 8 minutes.

“If we assume one shift at 8 hours a day (2,080 hours a year) at 85 percent efficiency, that is 1,768 hours available per year,” Abbas calculates.

By another measure, the abrasive saw at 45 seconds per cut can produce 141,440 cuts while the band saw at 8 minutes can produce only 13,260 cuts. “That means you will need 10 band saws to make the same number of cuts. More band saws will mean increased floor space required, higher upfront investment, and increased labor hours. With substantial shortages of industrial employee talent, productivity becomes the investment driver. “The advantages of an abrasive saw would be faster cycle time, and lower total cost per cut,” versus, says Abbas, band saws which require higher maintenance, a larger manufacturing footprint and a greater upfront investment cost.

Sawing Equipment Safety

With its machines, Savage Saws offer safety enclosures and sensors, which keep operators out of danger zones. Its enclosures feature a strong, lightweight aluminum frame; and polycarbonate panels that provide shielding from cutting motions while allowing for a clear view of the saw while it is operating. A side opening allows the infeed pusher assembly to feed steel alloy bars into the cutting head safely and a safety door with magnetic locks allows for ease of maintenance.

A safety sensor uses an infrared plane in front of the infeed pusher assembly. If the infrared plane is broken, the infeed pusher assembly will stop automatically while the cutting head continues to function separately. Mounting of the sensor is placed for the most effective range and coverage, so that the device does not get in the way of the cutting operation, Abbas says.

Savage Saw customers place safety as a top priority, alongside equipment durability. Sayre says, “At Parker Hannifin, we want machines that are safe and that will run without high maintenance. We will buy a saw that lasts 20+ years rather than 10, which is why we choose Savage Saws.”

Thermatool Corp., East Haven, Connecticut, 203/468-4100, savagesaws.com, thermatool.com.

Parker Hannifin, Mayfield Heights, Ohio, 800/272-7537, parker.com.