HAZControl™ Technology Upgrade – v4.1

Repeatable, Precise Heat Input Controls for Thermatool® HF Welders

Thermatool continues to pioneer new technologies to improve the tube and pipe making process. Currently with HAZControl™ Technology, our predictive algorithms calculate the initial recommended HF welding frequencies (HAZ Width) and power settings (HEAT). You can then store your recipes – simplifying complex welding variables, and deliver uniform, repeatable weld characteristics with minimum scrap. Thermatool HCT HF Welders deliver the most precise weld heat input control available.

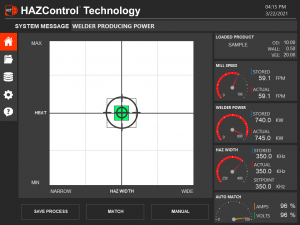

With the easy-to-use interface, operators can easily adjust the frequency or weld power according to each mill setup and respond to mill speed changes on the fly to get optimal and consistent weld results. A visual parametric process window is used to guide even the most inexperienced operator to the optimal weld heat input for a given tube or pipe being HF welded. With any setup, there are variables that could potentially alter the weld heat input of the HF Weld. If this happens, the mill operator can be alerted quickly to process control parameters approaching out of specification limits to correct the process and avoid the cost of producing scrap and not delivering to customers on time.

To further enhance the mill operator’s HF Weld process awareness, Thermatool has developed a software and control upgrade package for the HAZControl™ Technology control console that will offer a visual indication of HF Weld parameters – power (kW) and frequency (kHz).

With a HAZControl™ Technology software upgrade package, new and essential tools such as an external LED light stack lights up green – when within process control limits, yellow – when nearing the control limits (80% of limit – user adjustable), or red – outside of user defined process control limits. The software screen will highlight the process window background green, yellow or red, with a direct feed to the LED stack to alert the operator from a distance. When the weld parameters are within control limits, the HAZ grid background will remain white with the process window center – green.

This upgrade will also light the green LED on the console LED stack indicating that the HF Weld process is performing within limits. The control limits are set according to validated process parameters and are then indicated by a “process window” with a simple reticle (cross hairs) centered on the process center line when the stored recipe is first recalled. When the reticle appears outside the defined control limits the background and LED stack will change colors accordingly – keeping you on top of your process!

Features

- The HAZControl™ Technology software background will change colors accordingly – letting you know instantly when to make corrections. User defines all process control parameters and limits.

- An external LED stack will light up with the appropriate color – giving a visual indication to mill operators from a distance.

- Control limits are saved along with recipes for each product type – bringing the skill of your best process operators to everyone working on the mill.

- The upgrade requires no changes in the PLC program or additional wiring in the power supply cabinet – saving time and money at installation.

- Previously stored recipes can be migrated to the new control software.