Material Handling

For every Savage Saw you purchase, engineered material handling equipment is also available upon sight review by Thermatool Corp.’s technical staff.

Features

Automatic Bar Loader

The load table consists of a fabricated frame that has inclined ramps to allow the bars to gravity roll to hard stops at the end of the table. At the end of the table there is a pneumatic cylinder actuated escapement to remove one bar at a time from the table to allow it to roll onto the saw feed conveyor. There is also a single point adjustment to allow single bar escapement.

Infeed Pusher

The rack and pinion precision pusher system functions by having the material rest on an idle roller and then a pusher infeed laser detects the lead end of a new bar for auto trim cut. Linear bearings for pusher come with auto lubrication. The Infeed pusher accuracy is +/- 0.010”. This system is powered with a servo motor for precise bar movement.

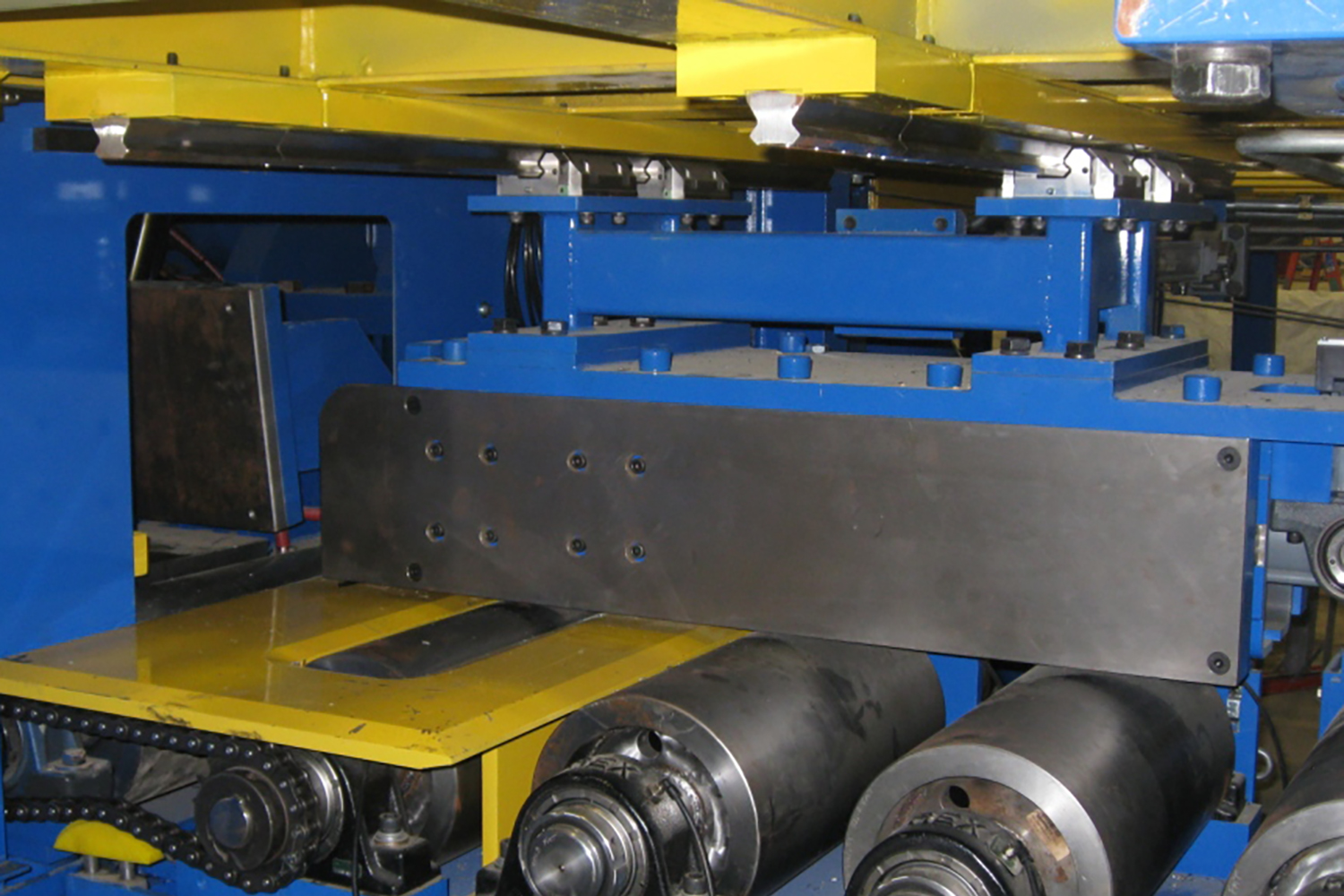

Outfeed Chain Driven Pusher

The outfeed roller conveyor is a chain driven roller conveyor that receives rounds and/or shapes from the Savage Saws and conveys the material to be dumped into the customer provided cradle for pick up. The rollers have a 12” effective width and are mounted to housed roller bearing.

Automatic Crop Reject Pusher

The automatic crop reject pusher has a hydraulic cylinder with linear guides that automatically pushes crop cuts into a customer provided bin after a cut is complete. This system is located at the exit of the saw and is integrated with the outfeed conveyor.